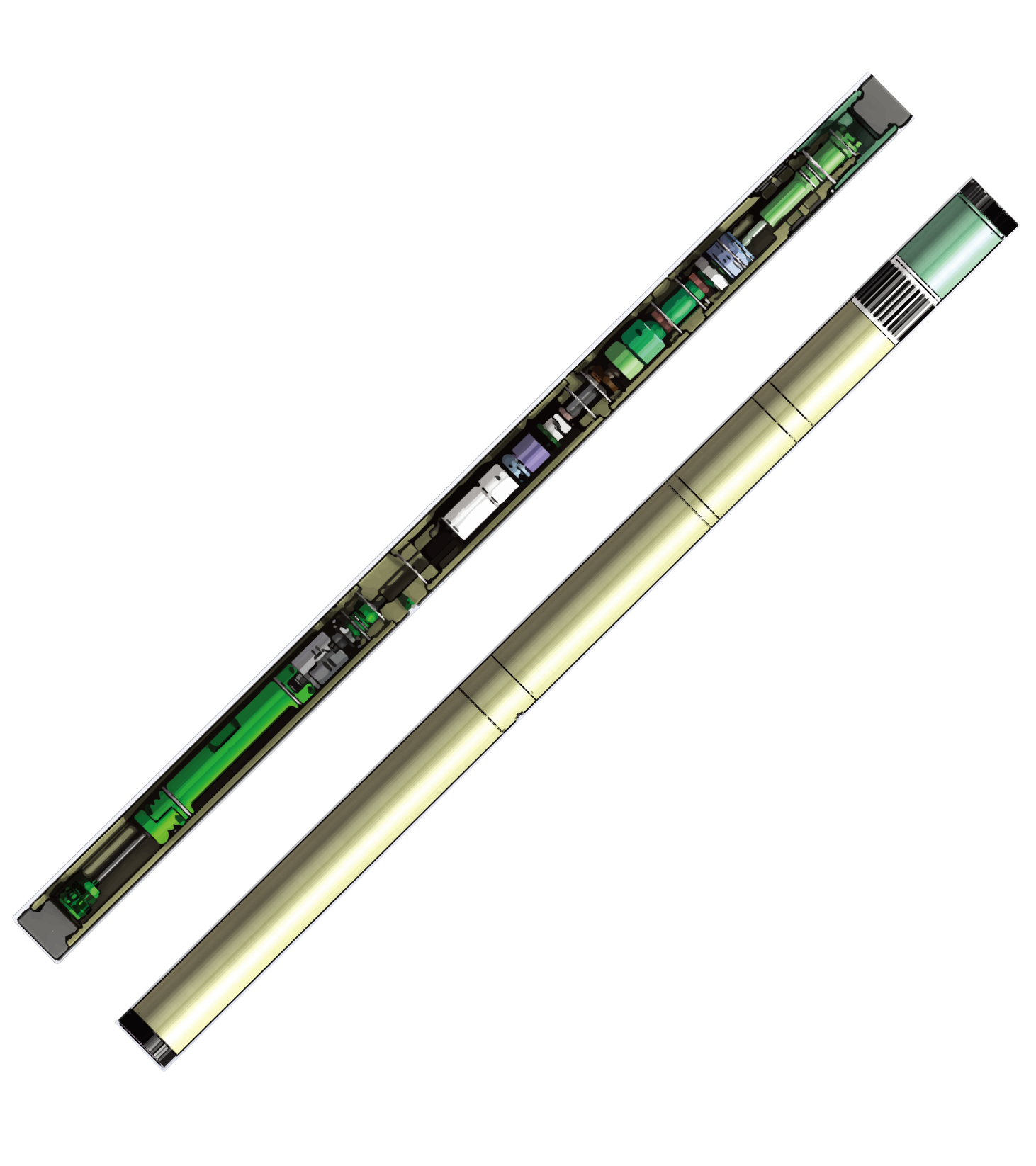

滚珠丝杠电机式脉冲器

产品简介

钻井液脉冲技术是目前随钻测井中使用最为普遍、最为可靠的一种方法,钻井液脉冲技术的核心是钻井液压力的产生机构即脉冲发生器。

目前广泛使用的电磁阀脉冲器是通过电磁阀的吸力来提升阀杆,靠弹簧的回复力使阀杆放下。 电磁阀脉冲器的缺陷有:第一、电磁阀磁铁的磁特性受材料的制约,磁性能不能进一步提高;第二、电磁阀效率低,损耗电池电能较厉害;第三、电磁阀的阀头拉力/ 推力较小,不能满足深井的工作需求。

滚珠丝杠电机式脉冲器可以解决这些不足之处,其工作原理为:电路控制直流无刷电机转动,电机通过柔性联轴器与滚珠丝杠联接,将旋转运动转变为直线运动,滚珠丝杠的丝母与阀杆联接一起,通过控制直流无刷电机正(反)转工作,便可实现脉冲器阀杆的拉起和放下。

产品特性

● 工作电流小耗电低,静态工作电流<12mA,28V供电一个脉冲1秒耗电125mA。

● 通过电流反馈可精准控制阀杆的拉起与放下。

● 电机工作电流0~3A可调。

● 具有过流保护。

产品应用

● 适用于深井(超过6千米)、高密度泥浆,高含沙量泥浆等复杂的随钻测量环境。

● 适用小井眼定向/水平井施工。

产品参数

| 仪器直径 | 38.1mm(1.5") |

| 仪器长度 | ≤1400mm |

| 仪器工作电压范围 | 20Vdc~36Vdc |

| 整机功耗 | 静态工作电流 <12mA,125mAmp*sec/pulse@28V |

| 丝杠行程 | 2.54±0.1mm |

| 阀头拉力/推力 | ≥25Kg |

| 工作温度 | 0~175℃ |

| 最大工作压力 | 172MPa(25000Psi) |

| 随机振动 | 20grms,30~1000Hz |

| 抗冲击 | 1000g/0.5ms 1/2 正弦波 |